Explosion and fire protection

with innovative safety structure

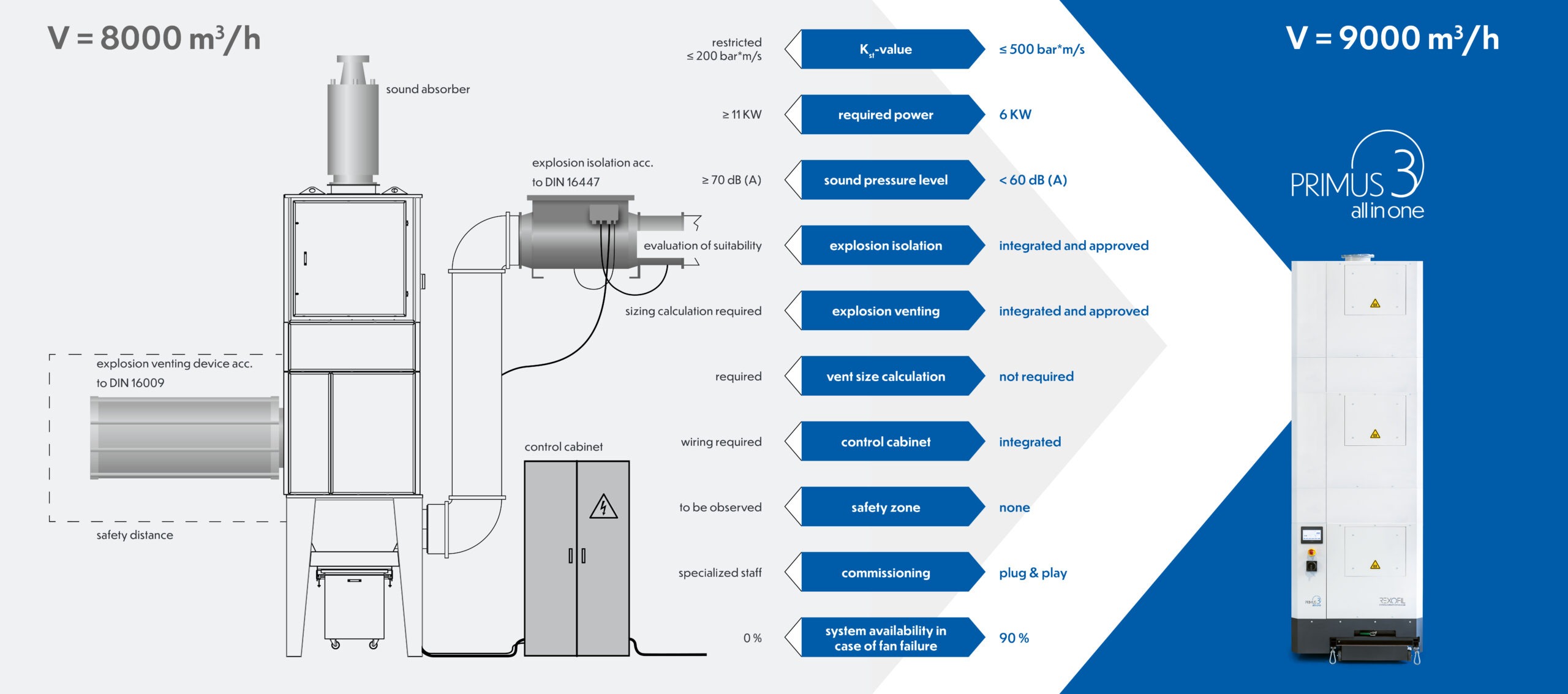

The PRIMUS – all in one was designed for highly explosive dusts and successfully tested according to ATEX Directive 2014/34/EU.

which could lead to explosion propagation towards system components upstream of the dust collector.

Demonstration of performance

The testing body certified the following result:

The system is suitable without restrictions for light metal (aluminium, magnesium, etc.), metal, and organic dusts with KSt ≤ 500 bar*m/s.

No hot surfaces were found.

The dust collection system can therefore be operated without additional autonomous protective systems (such as explosion venting devices according to EN 14797 or EN 14491) and without an explosion isolation system conforming to EN 15089 or EN 16447.

Calculations based on dust explosion characteristics – which, especially with metal dust, can be complicated and prone to errors – are no longer required. Design errors can result in the complete destruction of filter housings and in severe damage to the surrounding area.

Important notice:

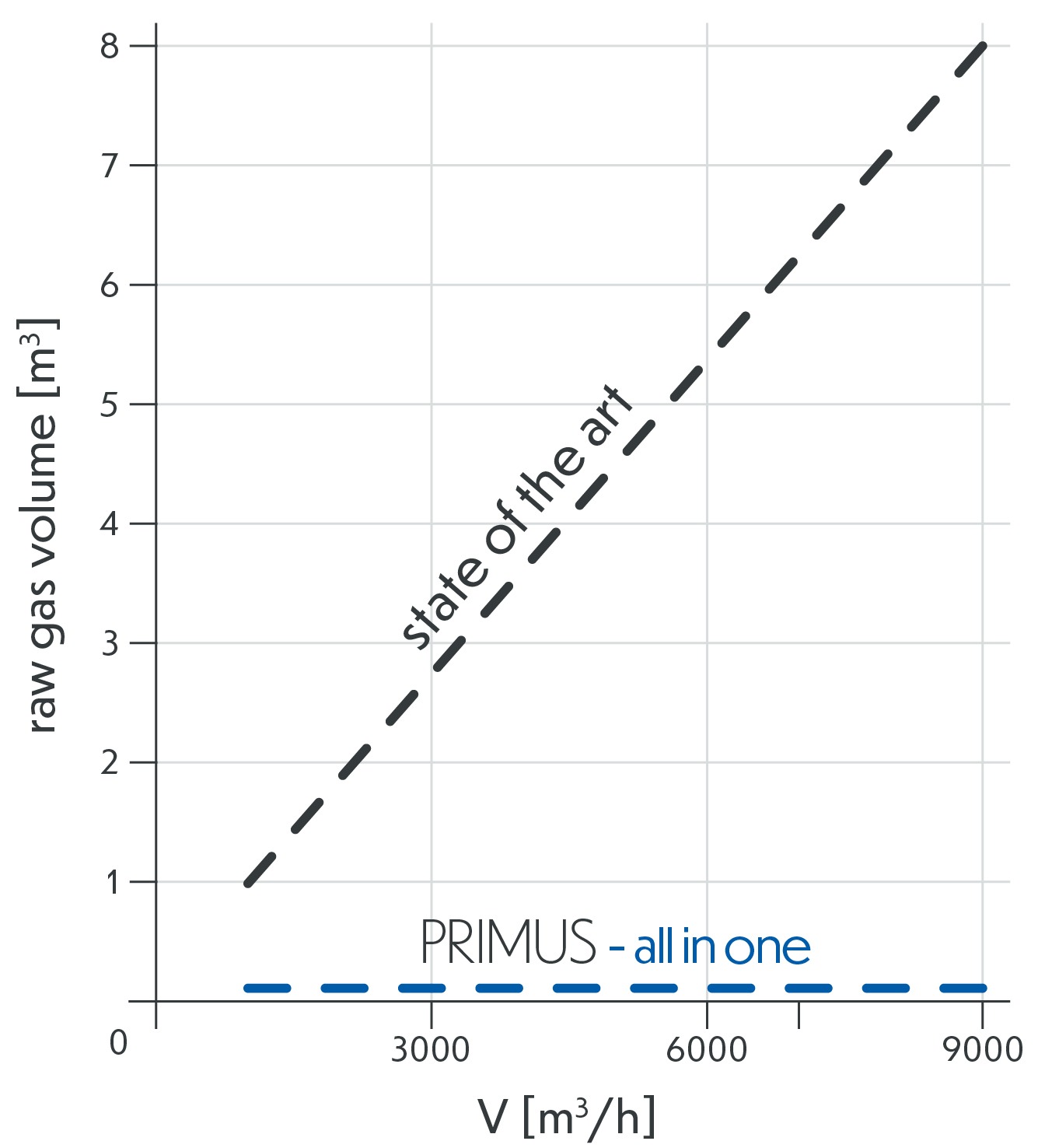

Please note that extremely violent explosions can occur inside the housing even in case of small raw gas volumes (< 100 litres), especially when light metal dust is handled. Even though standards may have limited scopes of applicability, it would constitute gross negligence to assume that no explosion can occur if the raw gas volume is less than 100 litres.

For reasons of safety, we advise against collecting such dust in filter systems with large raw gas volumes (> 4,000 litres), as is sometimes considered.

The PRIMUS – all in one is currently the only system in which the raw gas volume remains constant as the air flow increases.

System testing and approval

During the examination procedure of a system, examiners are likely to ask questions about the autonomous protective systems, which are typically required.

If you have questions or doubts about our novel dust collection system, we would be happy to provide any information you need.

Please feel free to contact us at any time.