Superior technology

Safety, functionality, sustainability

The PRIMUS – all in one modular dust collection system

Patented explosion suppression device with spark trap

Clean gas outlet

with HEPA filter or vent pipe to the outside.

Fan housing

Control cabinet

Greater flexibility for our customers thanks to a modular design

Filter cleaning without compressed air with the novel EFC system

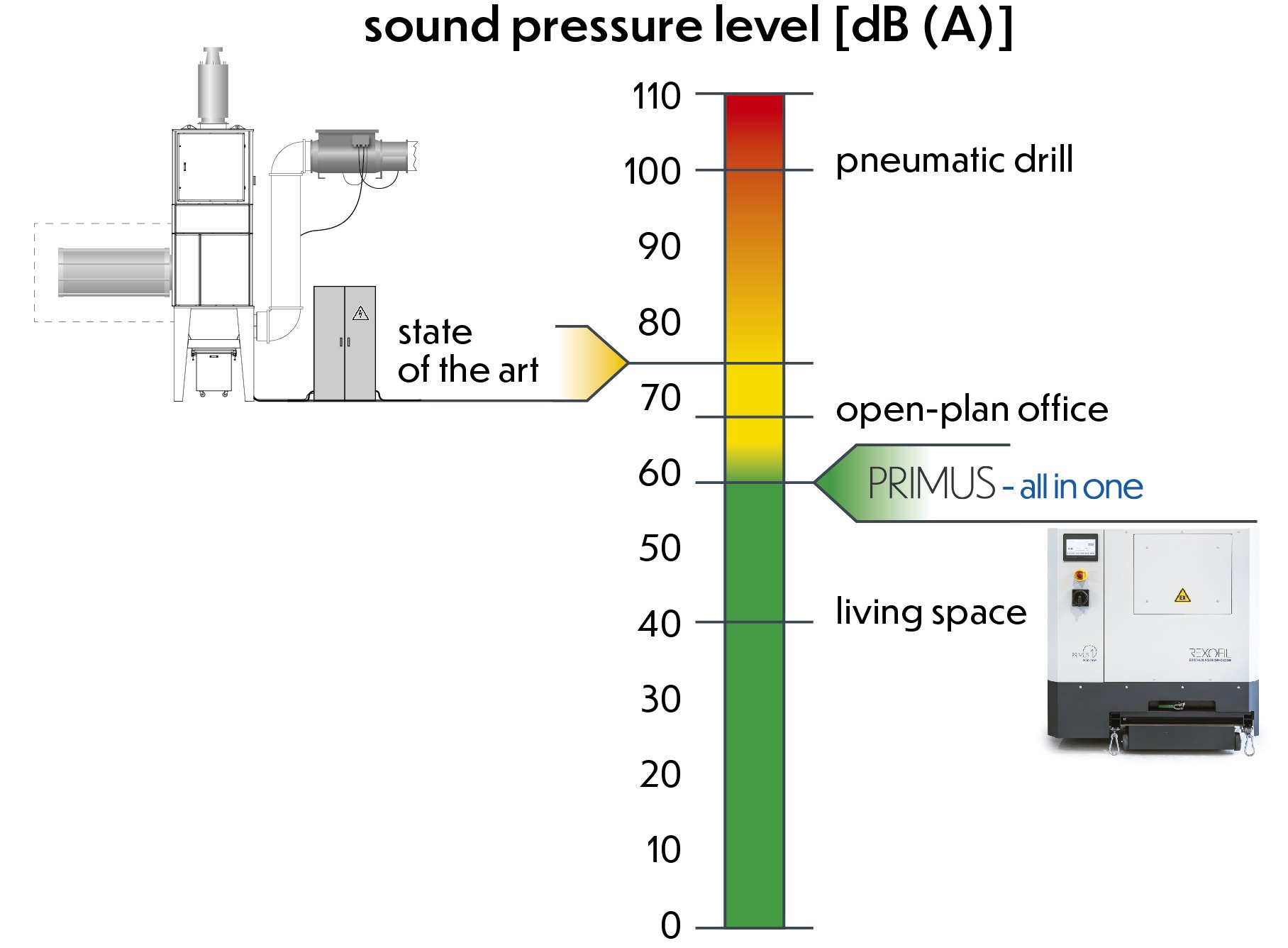

Sound insulation – sound pressure level < 60 dB(A)

Rotary feeder with large storage container

A fan conveys the dust through a rotary feeder into a tightly sealable standard storage container (barrel) with a volume of about 220 litres. To dispose of the dust, the barrel is simply replaced by another.

The air flow rate can be increased from 3,000 m³/h to 6,000 m³/h or even 9,000 m³/h at operating pressure without increasing the raw gas volume (about 80 litres). Since an increased raw gas volume involves a higher risk of violent explosion, the PRIMUS- all in one system provides inherent safety advantages.

Constant volumetric flow rate

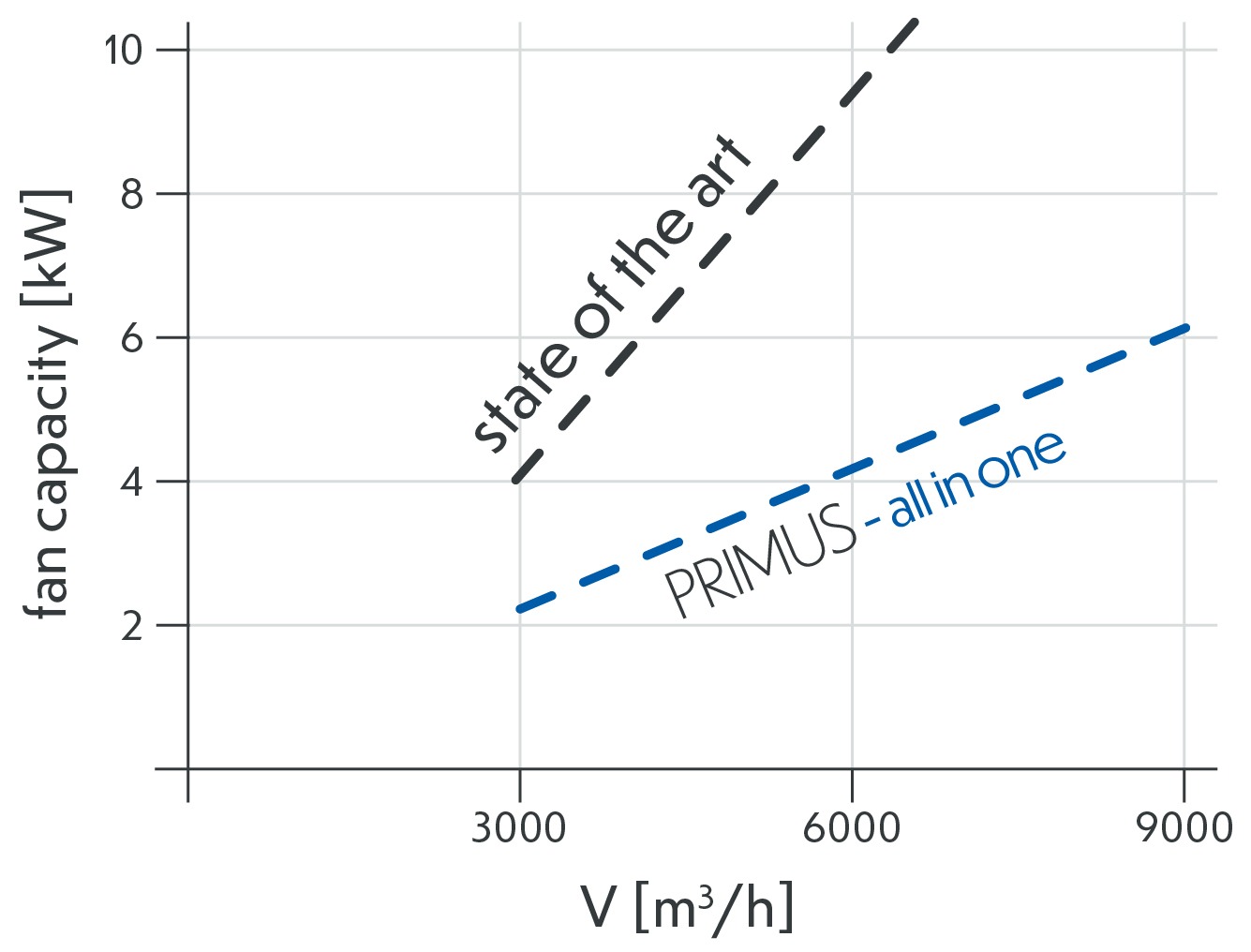

Unparalleled energy efficiency

System availability

Each module of the PRIMUS – all in one system provides full functionality.

If one module fails, the other modules can partially or completely provide the required air. This makes the PRIMUS – all in one a true game-changer in terms of system availability and flexibility.

Operating costs

- Only 2.2 kW are required for achieving an air flow of 3,000 m³/h at operating pressure.

- Filter ruptures are a thing of the past.

- Housings protect the filter elements from damage and wear.

- Costs are minimized thanks to the elimination of high-maintenance components and easy access to all relevant parts. In contrast, annual maintenance of autonomous protective systems of other dry dust collectors or the obligatory monitoring of wet scubbers can have a significant impact on the budget.

Environment and sustainability

To support your investments in improving energy efficiency and saving resources, you can apply for government subsidies and low-interest loans to considerably reduce your expenses.

Dimensions

| Unit | PRIMUS 1 | PRIMUS 2 | PRIMUS 3 | |

|---|---|---|---|---|

| Operating volume flow rate | [Bm³/h] | 3.000 | 6.000 | 9.000 |

| Width | [mm] | 1.150 | 1.150 | 1.150 |

| Depth | [mm] | 1.650 | 1.650 | 1.650 |

| Height | [mm] | 1.300 | 2.450 | 3.600 |

| Weight ca. | [kg] | 1.350 | 2.500 | 3.800 |

| Fan power | [kW] | 2,2 | 4,4 | 6,6 |

| Sound pressure | [dB(A)] | 60 | 60 | 60 |

| max. Kst value | [bar*m/s] | 500 | 500 | 500 |

Connecting the system

- CEE plug (16 or 32 A; 5-pin; IP44)

- Connect exhaust duct (DN 250 Jacobs)